In the world of luxury watchmaking, precision is not just a goal—it’s an expectation. Every detail, no matter how small, contributes to the overall accuracy and performance of a timepiece. From the movement inside to the case and dial, meticulous attention to every component is key to achieving the perfect timekeeping experience. One of the most intriguing aspects of high-end watchmaking is the micro-technology involved in the process. These intricate fine-tuning techniques, often invisible to the naked eye, enable manufacturers to create timepieces that perform with unparalleled precision.

In this article, we will explore how micro-adjustments and attention to detail in watchmaking achieve the high level of precision that discerning collectors and enthusiasts demand. From movement calibration to finishing techniques, we will break down how micro-technology influences a watch’s accuracy, longevity, and overall performance.

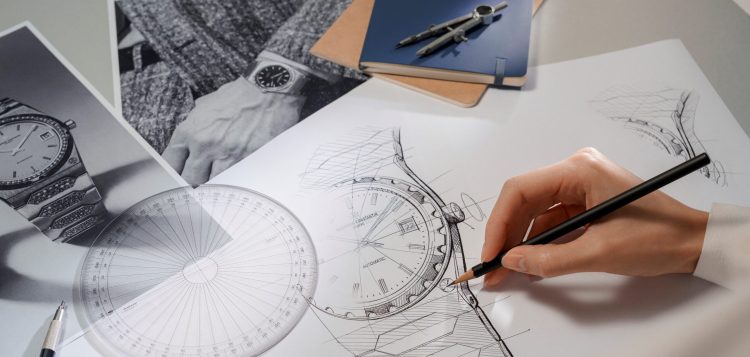

1. The Role of Micro-Technology in Movement Precision

The core of any high-end watch is the movement—the complex mechanism responsible for driving the hands and keeping time. The accuracy of a watch depends largely on the precise assembly and adjustment of its movement. Watchmakers employ a range of micro-technological techniques to achieve optimal precision and efficiency within the movement.

The Balance Wheel and Escapement: The Heart of Precision

The balance wheel and escapement are two critical components in a watch’s movement. These parts regulate the flow of energy and determine the watch’s accuracy. A slight miscalculation or poor adjustment can cause the watch to run too fast or too slow.

- Micro-Adjustment of the Balance Spring: The balance spring, also known as the hairspring, is a crucial component in controlling the oscillations of the balance wheel. Watchmakers fine-tune this spring using micro-tools to adjust its length and tension. Any imperfection in the spring’s shape or alignment can lead to discrepancies in timekeeping. Advanced Swiss escapements and chronometer-grade movements rely on microscopically precise balance springs to achieve maximum performance.

- Regulating the Escapement: The escapement releases energy from the mainspring in small, controlled increments, driving the movement of the hands. Micrometric adjustments are made to ensure that the escapement works at the most efficient level. Swiss lever escapements, for example, are adjusted by watchmakers using highly specialized tools to maintain optimal efficiency.

The Importance of Lubrication and Friction Minimization

Lubrication plays a crucial role in reducing friction between the various components of the movement, ensuring smooth operation and enhancing longevity. Watchmakers use micro-precision oiling to lubricate specific points in the movement.

- Oil Application: Excessive oil can slow down the movement or cause it to run irregularly. Conversely, insufficient lubrication increases friction, leading to wear and tear. Highly skilled artisans apply microscopically small amounts of lubricant to pivot points, gears, and the escapement, ensuring smooth and accurate operation over time.

- Synthetic Lubricants: High-end movements often use synthetic oils and grease, which are designed to reduce friction while maintaining stability at extreme temperatures. These advanced lubricants are precisely applied using special tools under microscopic magnification.

2. Micro-Polishing and Finishing Techniques: The Art of Detail

When it comes to luxury watches, micro-polishing is not just about aesthetics; it is a crucial part of ensuring the movement’s smooth functioning and accurate timekeeping. The polishing process reduces friction and ensures that each component works flawlessly without unnecessary resistance. Watchmakers use microscopic finishing techniques to create surfaces that are as smooth as possible.

Geneva Stripes and Côtes de Genève

The Geneva stripes (also known as Côtes de Genève) is a finishing technique that involves creating fine, parallel lines on the surface of the movement. This decorative pattern is more than just visually striking; it reduces friction by making the surface smooth and even.

- Micrometric Polishing Tools: Watchmakers use micrometric polishing tools to create these fine stripes, which are typically achieved by hand-finishing each individual piece of the movement. The precision involved ensures that each stripe is uniform, contributing not only to the beauty of the timepiece but also to its smooth operation.

Beveling and Chamfering

Beveling and chamfering are techniques where the edges of various parts of the movement, like bridges and plates, are carefully smoothed and rounded. This process serves two purposes: it improves the aesthetic appeal of the timepiece and reduces wear by ensuring that the edges do not create excessive friction when they interact with other components.

- Hand-Finishing: The level of precision required for beveling and chamfering is remarkable. Watchmakers use micro-tools, often polished to perfection, to carefully angle and polish the edges of each part. This attention to detail enhances the durability of the movement, ensuring that it continues to function smoothly over time.

Polished Screws and Gears

The screws and gears inside the movement are often polished to a high degree, reducing friction and enhancing the visual aesthetics of the watch. Micro-polishing ensures that even the smallest components are smooth and well-aligned.

- Screw Adjustment: The screws in a watch movement are often finely threaded to ensure a precise fit. Watchmakers micro-adjust these screws to ensure they hold each part securely without over-tightening, which could affect the movement’s performance.

3. Micro-Technology in Case and Dial Components

While the movement is the heart of the watch, the case and dial are the body and face. Watchmakers employ fine-tuning techniques here as well, adjusting and polishing every aspect of the case and dial for both aesthetic beauty and functional precision.

Laser Engraving and Etching

Today, high-end watches often feature intricate laser-engraved logos, serial numbers, and designs. The use of lasers allows for extreme precision in the engraving process, ensuring that even the smallest text is crisp and readable. These engravings are often executed with microscopic precision to ensure they are perfectly aligned.

- Micrometric Engraving Tools: Using advanced engraving techniques, microscopic tools etch fine details onto the dial, case back, and even the bracelet of the watch. This level of precision ensures that each detail is sharp and clear, further enhancing the luxury appeal of the watch.

Case Polishing and Surface Treatments

The case of the watch undergoes extensive polishing and surface treatments to give it its glossy or matte finish. The goal is not just aesthetic appeal but resilience. The case needs to be smooth to avoid skin irritation and to reduce wear from daily use.

- Microscopically Precise Buffing: Watchmakers use polishing wheels and micro-abrasive materials to buff the case and remove imperfections. The goal is to achieve a flawless surface that will resist scratches and other forms of damage.

- Surface Hardening: Techniques like PVD (Physical Vapor Deposition) coating are used to apply an extremely thin, durable layer over the watch case, offering enhanced scratch resistance. This layer is applied with microscopic precision and significantly enhances the longevity and appearance of the timepiece.

4. The Final Touch: Testing and Calibration

Once the micro-adjustments and finishing techniques are completed, the timepiece undergoes a final round of testing and calibration to ensure everything is working within the highest precision standards.

Chronometric Testing

High-end watches are often tested for chronometric accuracy, sometimes with instruments capable of measuring time deviations to the micromillisecond. Watchmakers may use electronic timing machines to test the watch’s accuracy over several days, making final adjustments to the movement until the watch is performing at its optimal level.

- Thermal and Positional Adjustments: The watch may also undergo tests under different temperature conditions and wrist positions to ensure that it maintains its precision in all environments.

Wrist Fit Testing

To ensure that the final product is not only precise but also comfortable, some high-end watches undergo wrist-fit testing. This step ensures that the watch sits properly on the wrist, the case is balanced, and the strap is adjusted for maximum comfort.

5. Conclusion: Micro-Technology in the Pursuit of Perfection

In the pursuit of perfect precision, micro-technology plays a critical role in every step of the watchmaking process. From the balance spring to the polished case, microscopic adjustments are necessary to achieve the uncompromising accuracy and luxury finish that collectors demand. Every detail, no matter how small, contributes to the overall performance, aesthetic appeal, and durability of a high-end timepiece.

By combining the art of fine-tuning with advanced technologies, luxury watchmakers have created watches that transcend mere timekeeping. They are masterpieces of engineering, craftsmanship, and innovation. For those who seek perfection, it’s the microscopic details—the fine adjustments and finishings—that truly define the excellence of the timepiece.